Global food security is intrinsically linked to soil health and resource availability. Degraded soils, erratic climate patterns, and excessive dependence on synthetic inputs challenge the resilience of agricultural systems. Emerging technologies such as biochar production equipment are increasingly recognized as tools to restore fertility and stabilize yields. By transforming agricultural residues into soil-enhancing carbon, these systems provide a direct pathway to strengthen food systems while mitigating environmental stressors.

Conversion of Residues into Soil Enhancers

The foundation of this approach lies in carbonization. A charcoal making machine processes feedstocks such as crop residues, wood chips, or husks under controlled thermal conditions with limited oxygen. The resulting biochar is porous, stable, and capable of retaining nutrients and moisture. This property is vital for regions with sandy or nutrient-depleted soils, where traditional fertilizers fail to sustain productivity. Unlike transient inputs, biochar endures in the soil for decades, ensuring long-lasting improvements.

Integration of Modern Biochar Production Units

In contemporary agriculture, scalability matters. Biochar production units are designed to accommodate varying capacities, from community-scale devices to industrial facilities integrated into agro-industrial parks. Their modular structure allows farmers and cooperatives to convert waste streams into high-value amendments directly at the source. This reduces transportation burdens and creates decentralized hubs of fertility enhancement. By situating production close to farms, nutrient cycles are closed more efficiently, contributing to localized food resilience.

Specialized Equipment for Coconut Residues

Tropical regions generate immense quantities of coconut husks and shells, often discarded or underutilized. A coconut charcoal machine transforms these residues into biochar with superior calorific value and agronomic benefits. The resulting product improves soil aeration and reduces acidity, conditions particularly beneficial for root crops and plantation systems. Beyond its role in soil management, coconut-derived charcoal also substitutes for conventional fuels, easing competition between energy and food sectors.

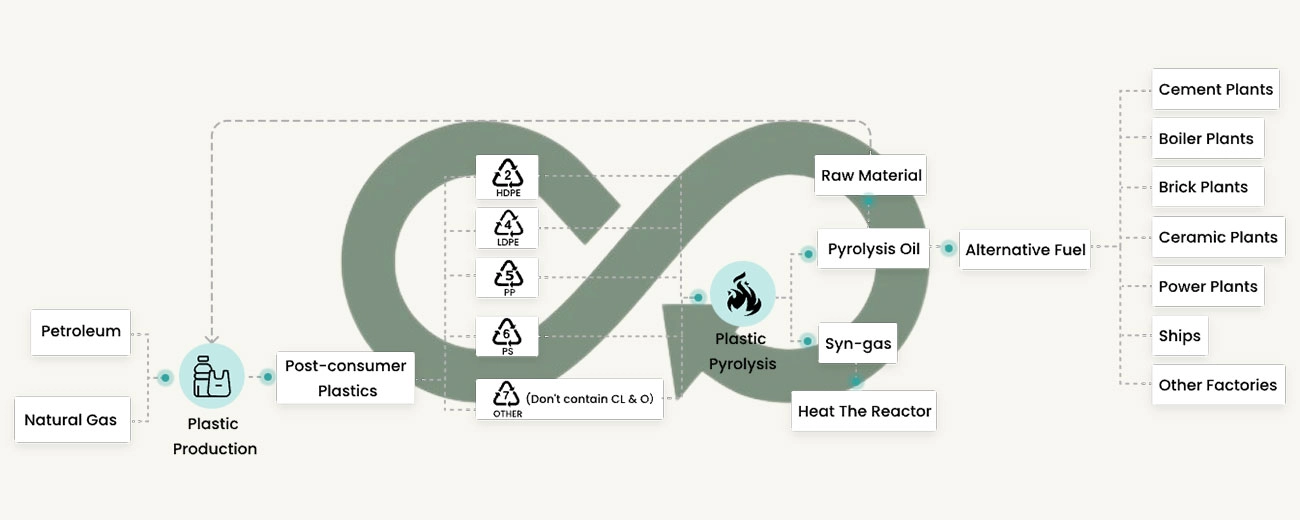

Role of Pyrolysis Plants in Sustainable Agriculture

At an industrial scale, a biomass pyrolysis plant for sale represents a strategic asset for agricultural economies. These plants not only divert organic residues from landfills and open burning but also provide a steady stream of soil amendments and renewable energy carriers. By integrating them into agro-industrial supply chains, regions can stabilize fertilizer availability, reduce chemical dependency, and enhance the long-term productivity of staple crops. The synergy between waste management and soil rehabilitation directly translates into greater food security.

Socio-Economic and Environmental Linkages

The adoption of biochar technologies extends benefits beyond agronomy. Farmers gain improved crop yields, reduced input costs, and resilience against climate-induced shocks. Communities experience cleaner environments due to reduced waste burning, while national economies strengthen by lowering reliance on imported fertilizers. Moreover, carbon sequestration through biochar aligns agricultural practices with global climate mitigation objectives, reinforcing the role of sustainable food systems in broader ecological strategies.

Conclusion

Biochar production equipment bridges the divide between waste management and agricultural sustainability. From the versatility of a charcoal making machine to the scale of biochar production units and the specialized application of a coconut charcoal machine, each contributes to restoring soils and securing harvests. With the availability of a biomass pyrolysis plant for sale, agricultural regions can institutionalize carbon-based amendments as part of their food security strategy. This technological pathway underscores how carbonized residues can become pivotal in nourishing both soils and societies.