In the realm of egg production and packaging, the egg tray machine plays a pivotal role in streamlining operations and ensuring efficiency. Central to its functionality are metal drying line, sophisticated systems designed to enhance the production process and quality of egg trays. This article explores the significance of metal drying lines in conjunction with egg tray machines, delving into their functionalities, advantages, and operational benefits.

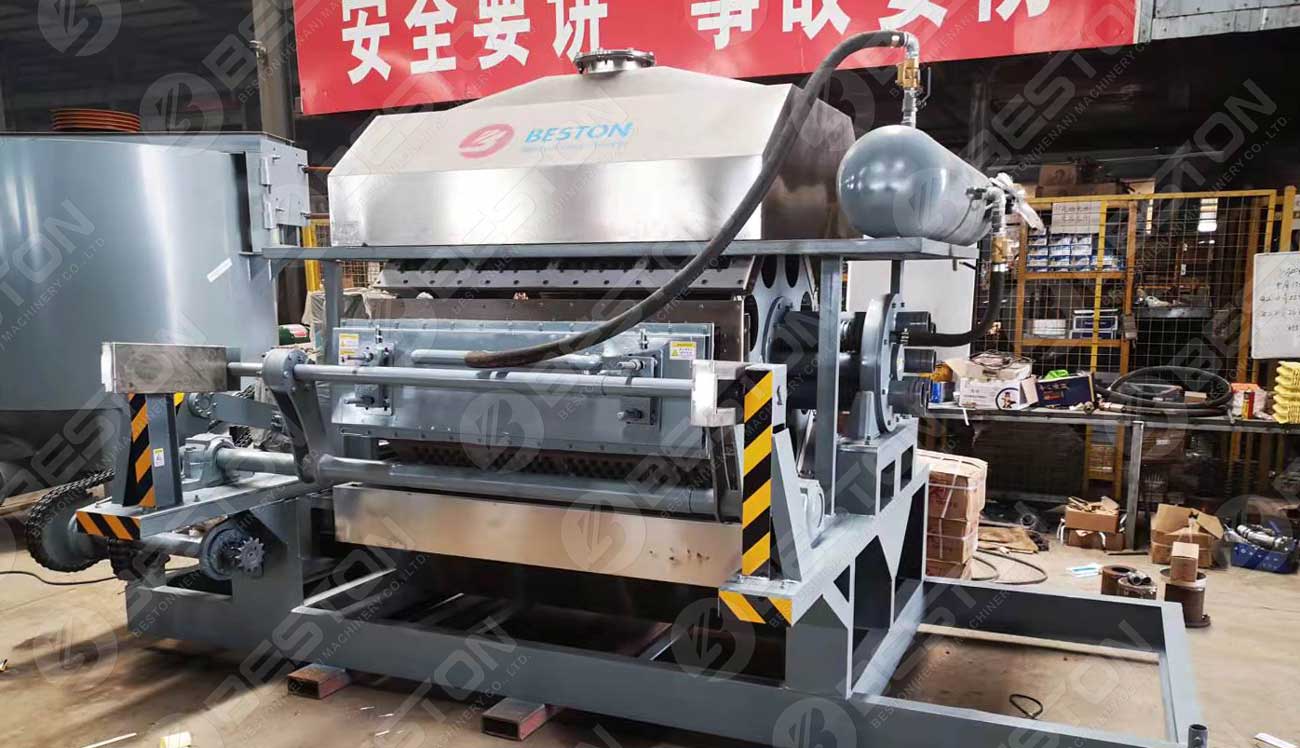

Understanding Egg Tray Machine

An egg tray machine is a specialized piece of equipment used in poultry farms and egg production facilities to manufacture trays for storing and transporting eggs. These machines typically utilize recycled paper or pulp as raw materials, which are molded into specific tray shapes and sizes. The trays produced are essential for protecting eggs during handling, storage, and transportation, thereby maintaining their integrity and freshness.

Key Components of an Egg Tray Machine

- Pulp Molding System: This system converts recycled paper pulp into molded trays through a series of processes including pulping, molding, and drying.

- Molding Dies: These are molds or templates that shape the paper pulp into various tray designs, such as 30-cell, 12-cell, or customized configurations.

- Drying System: Crucial for removing moisture from the molded trays to achieve optimal strength and durability.

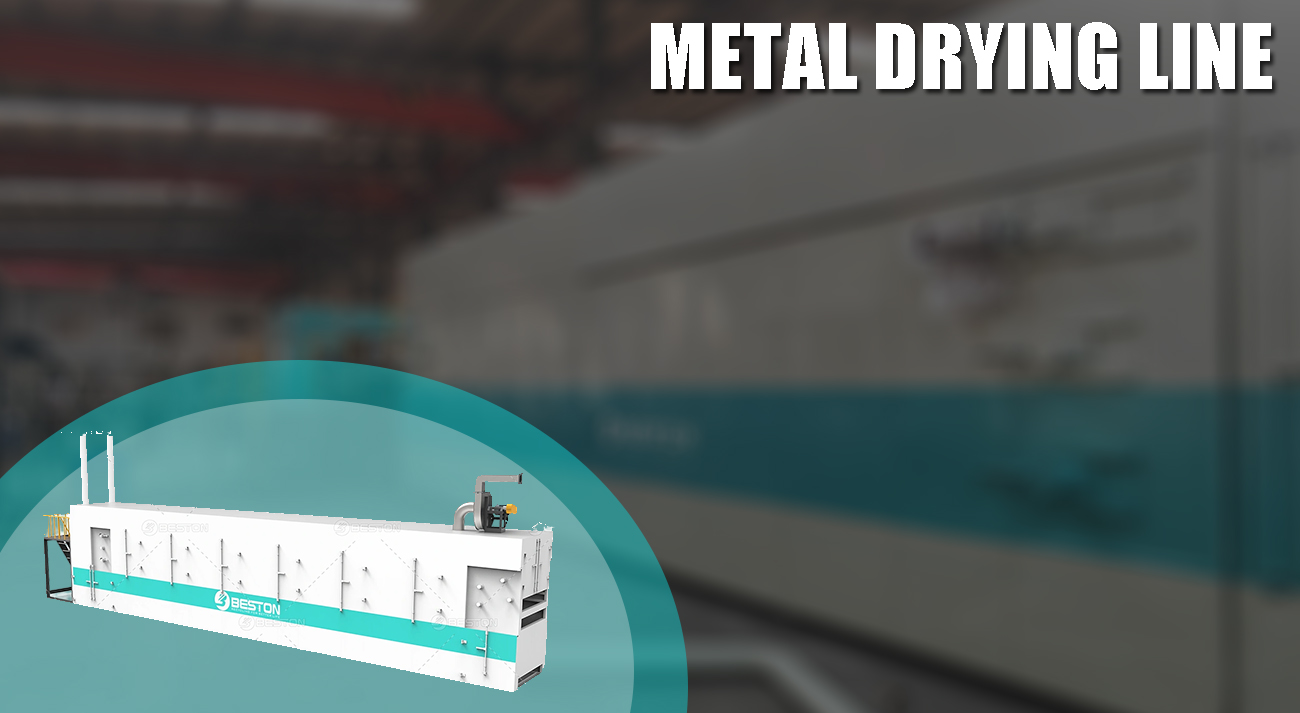

Role of Metal Drying Lines

Definition and Functionality

Metal drying line is advanced drying systems integrated into egg tray machine to facilitate the drying process of molded trays. Unlike traditional drying methods, such as air drying or sun drying, metal drying lines offer precision, control, and efficiency in moisture removal. These systems typically consist of conveyor belts made of stainless steel or aluminum, which transport trays through a series of chambers equipped with heating elements.

Advantages of Metal Drying Line

- Uniform Drying: The controlled environment of metal drying lines ensures consistent drying of egg trays, minimizing variations in tray quality and strength.

- Fast Drying Times: Compared to conventional methods, metal drying lines reduce drying times significantly, thereby increasing production efficiency and throughput.

- Energy Efficiency: Modern metal drying lines incorporate energy-efficient heating elements and insulation, reducing operational costs and environmental impact.

- Quality Assurance: By eliminating moisture effectively, metal drying lines enhance the structural integrity of egg trays, reducing the risk of deformation or damage during handling.

Operational Benefits

Production Scalability

- Metal drying lines allow for scalable production output, accommodating varying demand levels without compromising on tray quality or consistency.

Process Integration

- Integrated with egg carton making machine, metal drying lines streamline the production process by automating drying stages, minimizing manual intervention, and optimizing workflow efficiency.

Maintenance and Durability

- The robust construction of metal drying lines ensures longevity and reliability, requiring minimal maintenance and offering continuous operation over extended periods.

Technological Innovations

Automation and Control Systems

- Recent advancements in metal drying lines include the integration of automated control systems that monitor and adjust drying parameters in real-time.

- Sensors and digital interfaces provide operators with precise data on temperature, humidity levels, and tray throughput, enabling proactive maintenance and operational optimization.

Modular Design and Flexibility

- Modular metal drying line offers flexibility in configuration and layout, allowing manufacturers to customize drying processes according to specific tray designs or production requirements.

- This adaptability enhances operational versatility and efficiency, accommodating diverse product specifications and market demands.

Environmental Considerations

Sustainability and Resource Efficiency

- Metal egg tray dryer contributes to sustainability initiatives by reducing energy consumption and greenhouse gas emissions associated with traditional drying methods.

- Efficient moisture removal minimizes waste and enhances the recyclability of paper pulp, aligning with eco-friendly practices in egg tray production.

Future Perspectives

Emerging Trends and Innovations

- Future developments in metal drying lines are expected to focus on enhanced automation, digital connectivity, and energy efficiency.

- Integration with artificial intelligence (AI) and machine learning algorithms will enable predictive maintenance and adaptive drying strategies, further optimizing productivity and sustainability.

Conclusion

The egg tray machine stands as a cornerstone of modern egg production, supported by advanced technologies such as metal drying line. These systems not only streamline production processes but also uphold product quality, operational efficiency, and environmental stewardship. As global demand for sustainable packaging solutions continues to rise, the role of metal drying lines in enhancing the efficacy and eco-friendliness of egg tray production remains paramount. By embracing technological innovations and best practices, manufacturers can forge a path towards sustainable growth and resilience in the dynamic egg industry landscape. For more types of egg tray production lines, please consult Beston Group Co., Ltd.