The charcoal machine takes many types of biomass and turns them into charcoal. Whether you use coconut shells, rice husk, or waste wood, you can recycle waste biomass and convert it into charcoal with ease. This charcoal is top quality and it is easy to sell. The machine uses the latest carbonization technology to convert the material so you can make more money. Read on to learn how to get the best mobile biochar machine price so you can start making money.

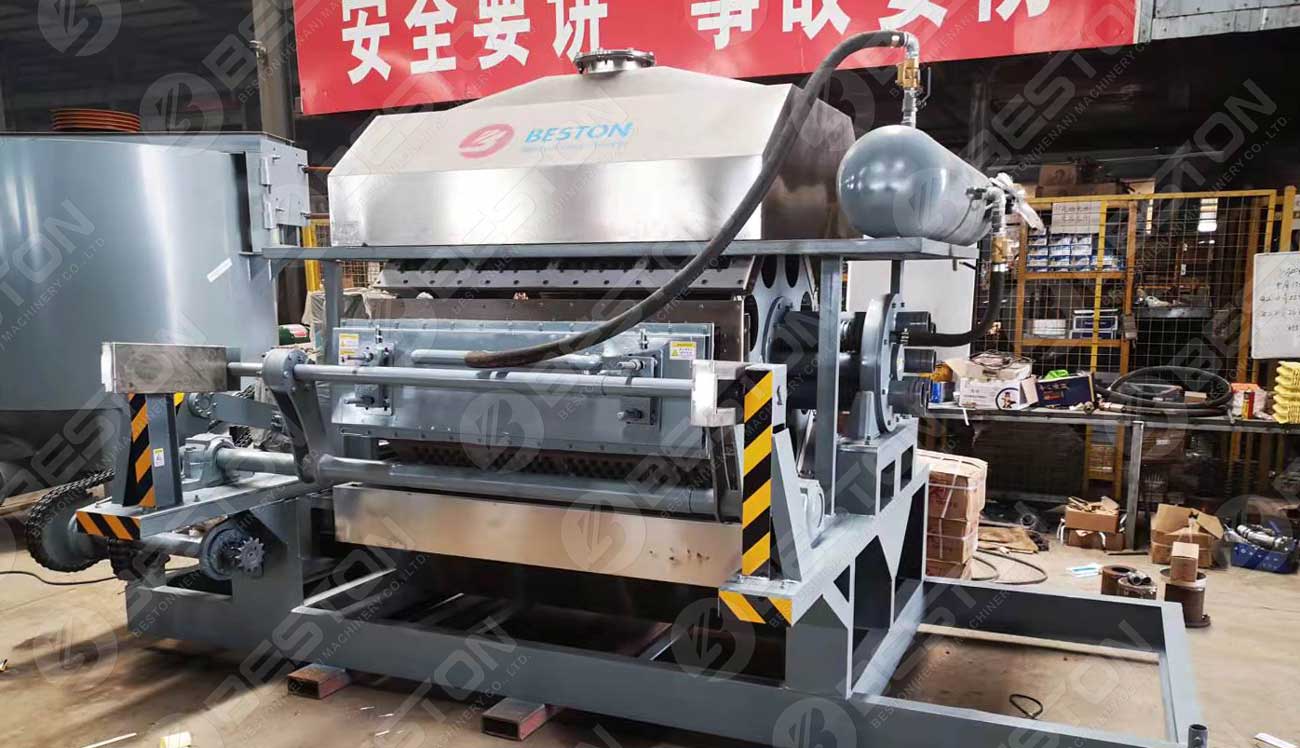

The charcoal machine is affordable and you can make huge profits with it. The machine can be exported to most countries and every machine is tested and guaranteed before it ships. You will enjoy the attention to detail and the smooth operation of the machine when you invest in a quality biomass carbonization machine.

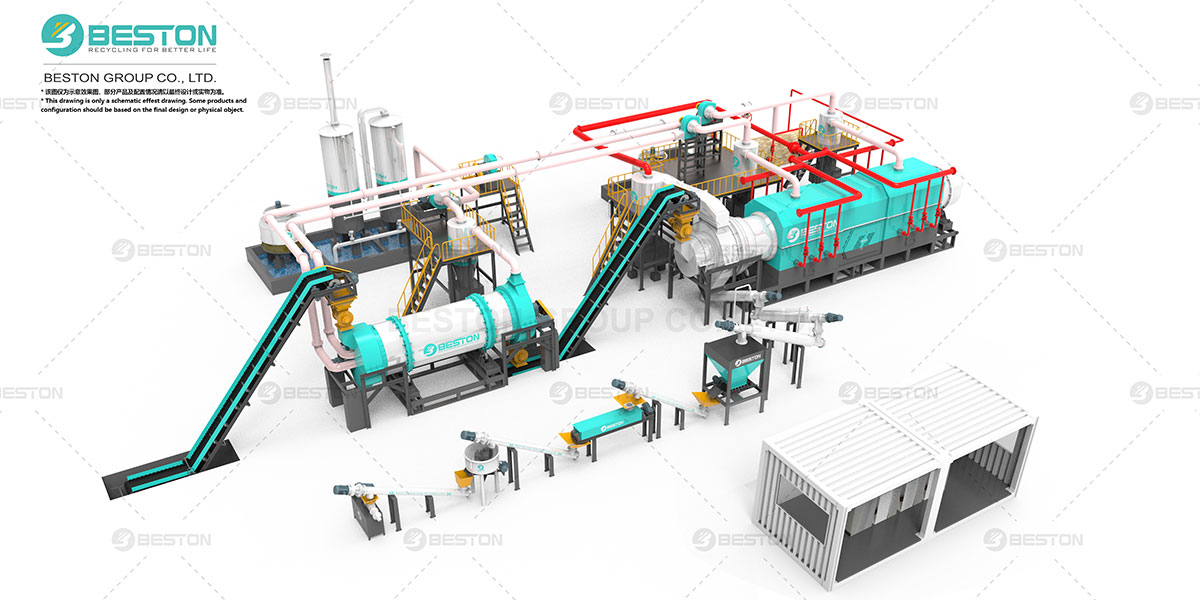

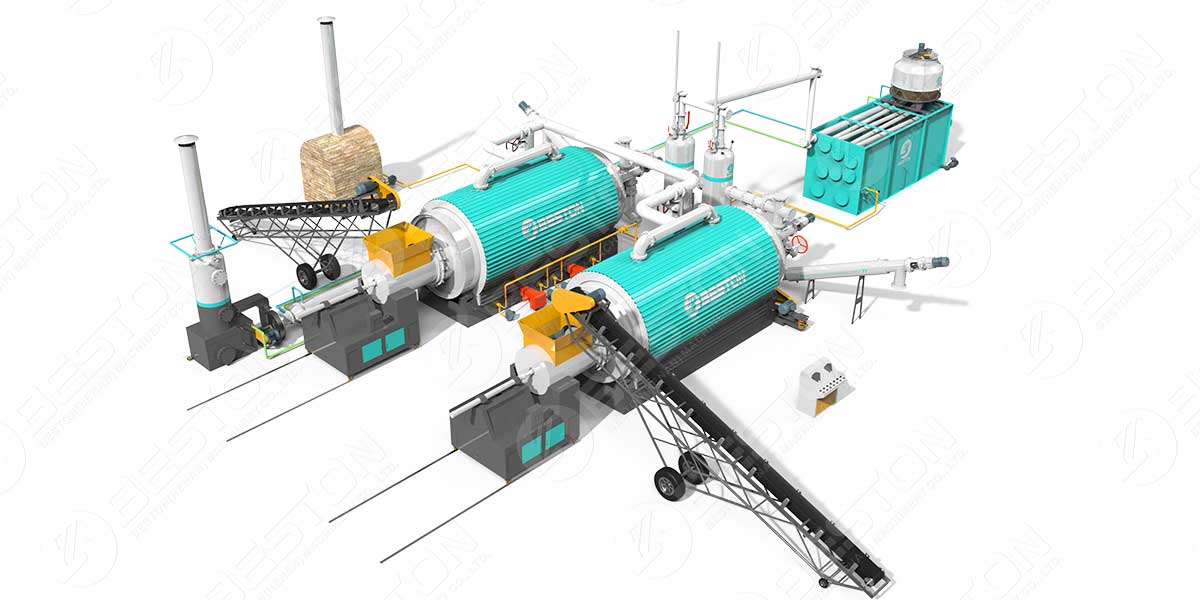

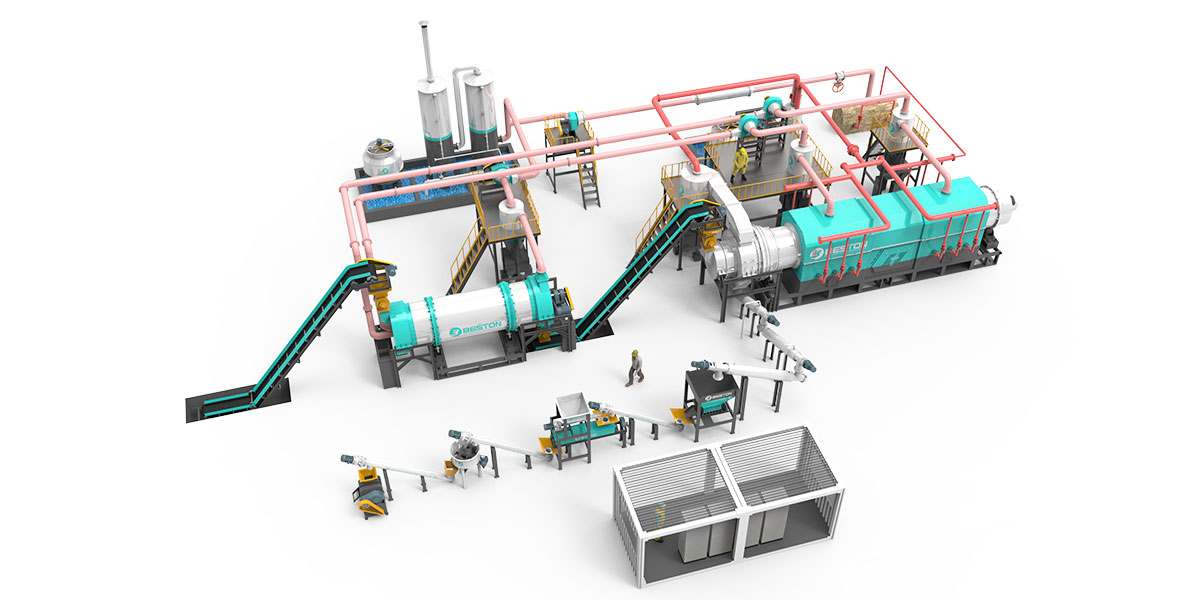

These machines use the most advanced technology to heat up the biomass and turn it into charcoal. The machines are also good for the environment since they convert waste into something useful. You can take many different types of biomass like straw, sawdust, palm shell, bark, and logs and convert them into charcoal.

The machine will heat up the biomass to a very high temperature where it is then converted into charcoal. Every aspect of the machine is designed to save energy. Even the heat of the machine is recycled. The machine has a dual layered chamber that holds in the heat and recycles it around the rest of the machine so you keep your energy costs down.

The charcoal that you can get from the machine can be used in many different ways. The charcoal is often used for heating and cooking. It is used for incense and it is also an ingredient in many different products. Charcoal is always in demand which means it is easy to sell. You can easily produce tons of charcoal quickly and sell it right away for a great price. The machine will help you make more money and it will run continuously so you can make money with it around the clock.

Find more applications of this machine: https://bestonasia.com/sawdust-charcoal-making-machine/.

Every machine is equipped with dedusting equipment that prevents any pollution from getting out. The machine is designed to be easy on the environment. The price of this machine depends on the features that you want and whether or not you want to have it customized.

There are many stock models to choose from and if you want special specs you can have the machine customized for an extra price. The price will depend on which model you order and how much automation you need with your machine. The best way to ensure you get the right machine is to work with the manufacturer so they can help you choose the best machine for your situation.

In general, the cheapest machine is the manual machine since it is less automated and relies more on labor to keep it running. The most expensive machine is the automatic machine. The manufacturer will help you choose the best charcoal manufacturing machine for your business.