The conversion of wood based products into charcoal has been done for centuries. This is something that you can do without machinery. Many people around the world have understood that smoldering wood can lead to the production of charcoal. Today, we have wood carbonizing machine that will do that for us. These machines are much more efficient at processing this type of material. You can feed various wood based products into the wood charcoal making machine for sale and produce charcoal by the tons. If you have a business that has access to a continuous supply of any type of wood based products, this is something that you should invest in.

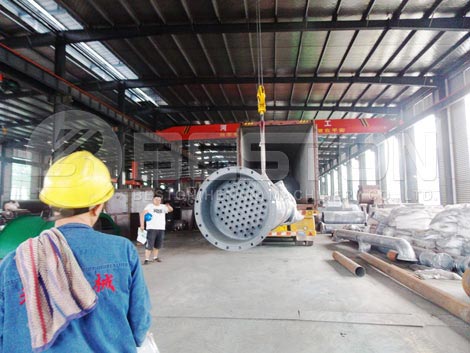

Wood Carbonizing Machine for Sale – Beston

How Do Wood Carbonizing Machines Work?

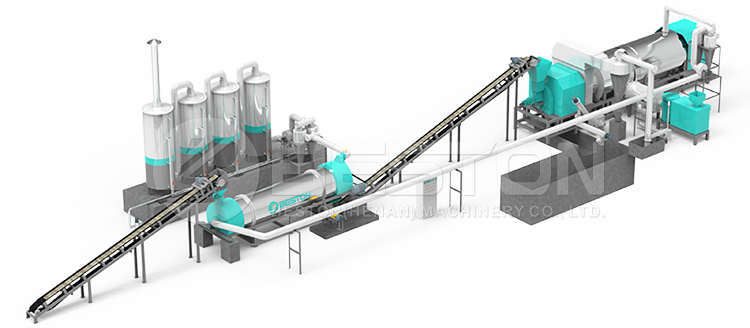

These pyrolysis machines work on a simple premise. They have a chamber where these materials will be placed. This could be anything from pieces of wood, bamboo, or even coconut shells. Therefore, it is also called charcoal manufacturing plant. Sawdust is also used for this process. Oxygen will be evacuated from the chamber and high temperatures will be obtained inside of this closed unit. This causes a chemical breakdown of the wood and leaves us with the residue of charcoal and liquid fuel.

Charcoal Made by Beston Wood Charcoal Making Machine

How Much Charcoal Can You Produce With These Machines?

The amount that you can produce is based on two factors. The size of the unit and its overall efficiency. If you are obtaining one of the latest models, and it is an entire pyrolysis plant, you could produce tons of charcoal every single day. For example, if you are responsible for a lumber company, or the harvesting of a crop like rice, these materials can be processed into charcoal within days. It’s an easy process to learn, but you do have to find the best machine that can offer you this capability.

Tips On Assessing These Different Products

They will provide you with a spec sheet which will detail all of the different components that are worth noting on these machines. They will tell you the model number, working method, and the raw materials that each machine can use. It is important to look at the hourly feeding capacity. If you have tons of wood that you can use every hour, then you will want a machine that can accommodate this need. Look at its lifespan, operating pressure, and the heating materials that it uses. Also think about the floor area, working method, and the reactor size for the machine you want to purchase. All of these factors contribute to making the best decision when obtaining one of these pyrolysis plants or machines.

Instead of simply discarding tons of wood base materials, you should instead convert this into a burnable fuel by wood carbonizing machine. The byproduct of charcoal is exactly what you will get when using them. The charcoal manufacturing plant works well with companies that have access to a large amount of wood. See parameters there https://bestonmachinery.com/charcoal-making-machine/bamboo/. Whether you are a small company, or an exceptionally large one, there will be a pyrolysis machine that is affordable for you. All of these factors will lead you to the right company, and the right product, that can help you convert your left over wood based materials into charcoal daily.