When you need a waste separation machine it is going to be very important to find a plant that is going to work the best for your needs. This plant takes a variety of types of waste and separates it into separate piles so you can recycle or sell the waste.

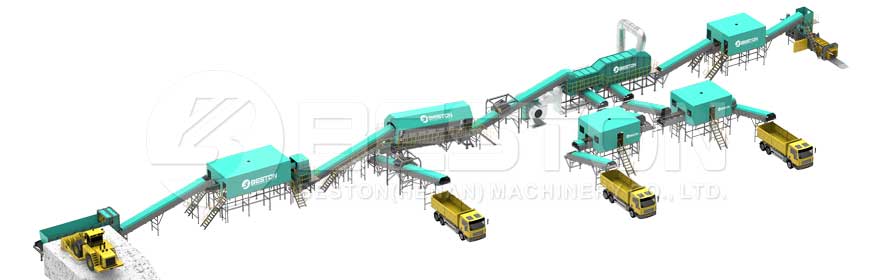

The plant is very efficient and you don’t need a lot of manual help when you are working with the plant. The plant is capable of sorting out metal, glass, plastic, bricks, and organic matter so it can be processed. This machine is important because it prevents so much waste from getting out into the system.

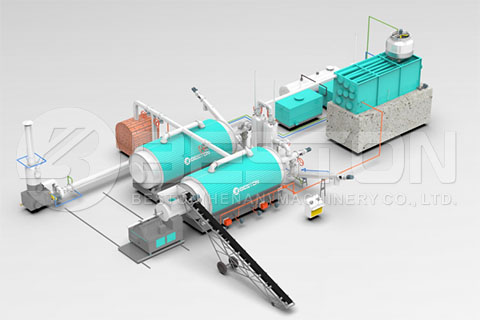

Waste Separation Plant Design

This machine is fantastic for the environment and it prevents waste from being put into the landfills. You can save a lot of money when you use this machine and it is going to ensure that you get superior results. When you are looking for a sorting system you can count on you want to make sure that you use this system because it is going to work flawlessly to ensure that little waste gets out into the landfills.

You have to make sure that the waste is going to be sorted and that you don’t have to deal with issues from it. The MSW sorting plant runs automatically. You just need to have people there to make sure that no large pieces get onto the conveyor belt.

The machine uses a variety of screens and other sorting equipment to sort all of the waste so that nothing gets out into the landfills. The machine is easy to set up and use and it works efficiently to ensure that you get the best experience.

The machine is safe to operate and it can operate with ease to ensure that you get all of the waste sorted out in the most efficient way possible. When you need a very efficient waste segregation plant you want to make sure that you use this machine since it makes it so easy to get things done.

As the waste is placed on the conveyor belt, the workers sort out all of the large objects that can’t get through the machine. You will need to separate large branches, tree trunks, clothing and other large objects out of the trash pile.

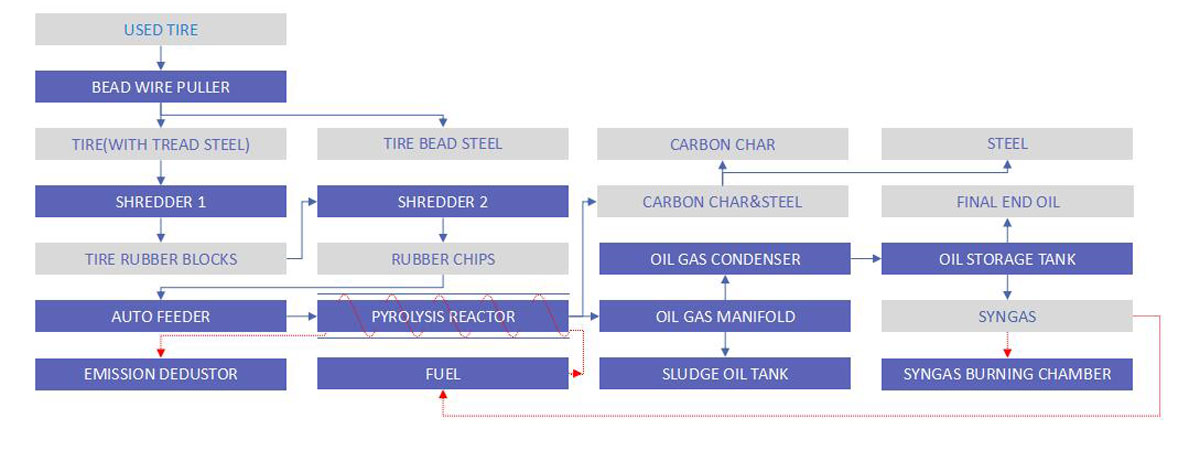

When the large waste is removed from the trash pile you can run the smaller items through the machine where they will be sorted. The waste moves to a screening machine and the screen plates will begin to separate the trash. Magnetic screens will extract the metal trash and organic waste will be sent for composting.

Rotary Screening Machine

The trash is going to be sorted into heavy materials like brick and stones and light materials. The solid waste management plant design is accurate and it can be configured to work in a variety of ways. The computer control system is easy to use and there are special odor barriers installed that will keep the smell down. The segregation plant is good for the environment.