If you’re looking to get waste sorting equipment, you need to be cautious. You want to know that what you’re buying is going to work for you. That, and you want to make sure that you’re not paying too much. Here are some tips that will help you find the right tyre to oil plant for sale.

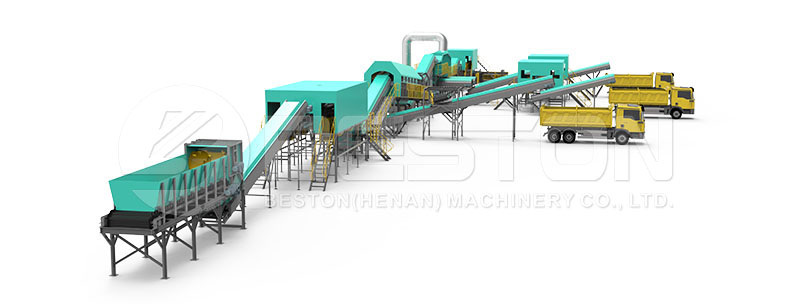

Waste Sorting Plant Design

Try your best to find waste sorting machines that are well made. To find out what is well made, you’re going to want to turn to online reviews. You can learn a lot about a machine if you find reviews on it because they tell you what other people went through when they bought something. You don’t want to buy something without doing a little bit of research or you may not be happy in the end. It’s good to find three or more reviews on something before you buy egg tray making machine just to make sure it’s right for you.

It’s important for you to find out what you are going to have to pay for a waste separation machine. You want to know that you’re paying what is fair for what you are getting. This means that you’re going to want to take your time and really look over your options so you know what this should cost you when all is said and done. You don’t want to find out after you buy something that you could have gotten a better deal if you did some digging. It may take time to shop around and look at prices but it’s worth it in the end when you’re able to save.

Waste Sorting Machine to Hungary

See if you can return a machine to get a replacement or to get it fixed if there is something wrong with it when you get it. Most companies will let you make a return as long as it’s not too far into the future. You generally have a month or so to return something if it’s not working right for you. Make sure you test a machine out right when you get it so if there are any problems you can work on returning the machine.

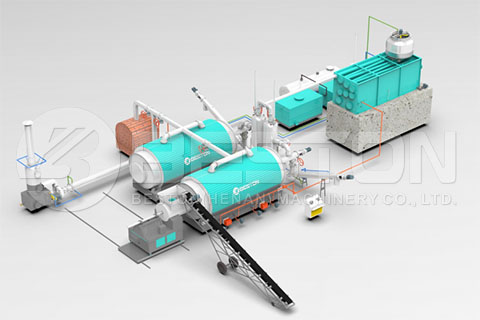

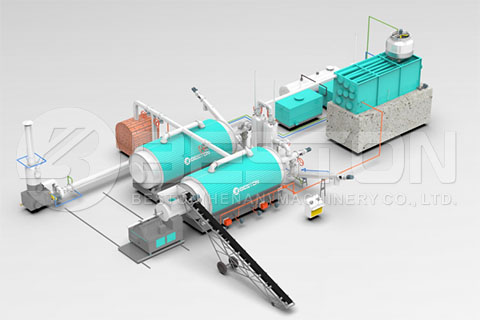

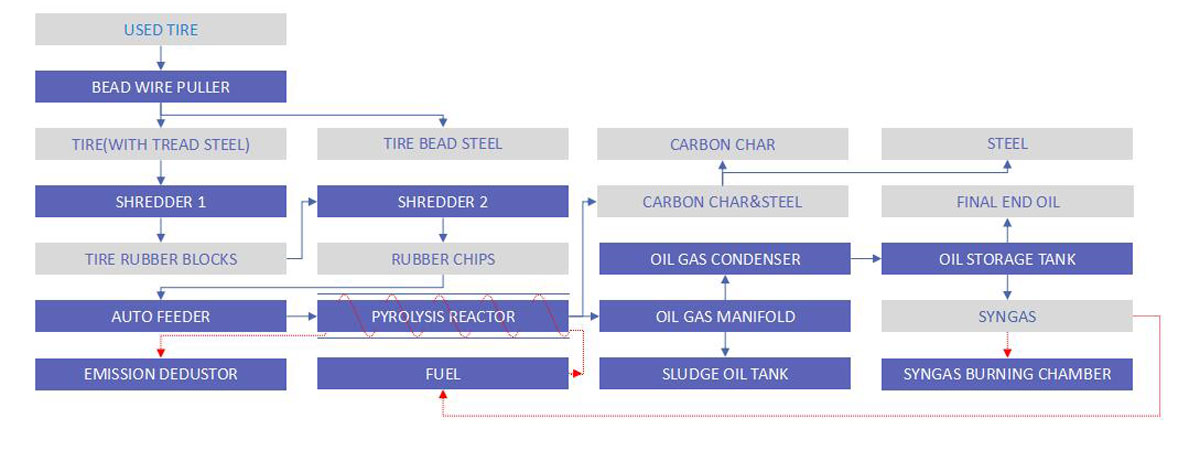

If you want to save some money, you may be thinking of buying a waste sorting machine that is small. If you want to get return soon, you can buy a further processing plant, such as waste pyrolysis plant, which can make you high-quality products to bring you more returns.

It’s important to find waste sorting equipment for sale that is going to meet your needs the most. There happen to be quite a few great options out there, you just have to look for them. Once you find what works you’ll be glad you did your research. Find more ways about waste recycling here: https://bestonasia.com/.