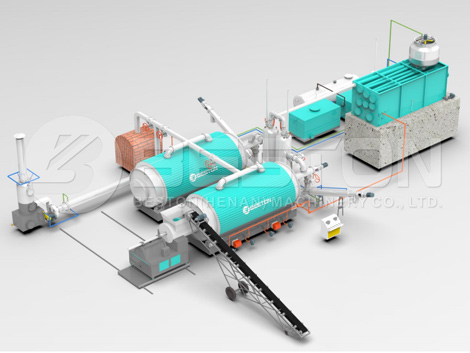

Tire pyrolysis plants are designed to do one. You can take chipped up tires, place them in the pyrolysis reactor, and then use them to create charcoal. There will be other byproducts including biofuel that can be burned as well. For the most part, your primary focus with a tire pyrolysis plant is to go through as many tires that you can. If you are working with a landfill, you are likely trying to empty it out or keep it from filling up. You can do this if you know where to obtain a reasonably priced tire pyrolysis plant.

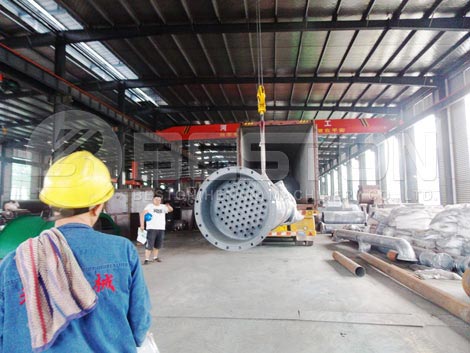

Planta de Pirolisis blj-10

Would You Need An Entire Plant?

You should probably consider getting an entire pyrolysis plant if you are interested in locating one of these systems. It is important to work with a company that can offer you the ability to choose between multiple units. In some cases, you will have thousands of options in terms of industrial equipment that they have to offer. You are specifically looking for a company that is known for creating tire pyrolysis plants that can overproduce charcoal. Therefore, if you have an entire landfill to work with, you would certainly want to have access to a tire pyrolysis plant.

Will It Be Easy To Find?

In most cases, it’s very easy to locate these companies. It should take you only a few minutes of your time. Within minutes, you will have the ability to request estimates on the total cost. Finally, will find a company that will offer you several options. These options will include a pyrolysis machine, a small pyrolysis machine, and an elaborate one that can go through hundreds of tons of material per month. Based upon how much material you have to work with, or if you have a municipal solid waste company that has a constant supply of them, the largest one available would be the best choice.

piscina

How To Get A Good Price On One

Getting the best possible price on these systems is easy to do. It’s only going to take you a few minutes of your time. You will eventually locate a company that will offer you a great deal. This could be for one of the largest systems that is comprehensive and elaborate. They may also offer a special price on shipping, particularly if they are also shipping different units to your area at the same time. You need to talk with the manufacturers and get these quotes directly from. This will help finalize how much you will pay and determine the shipping date for the item.

What Can You Expect With Tire Pyrolysis Plants?

What you will be able to expect is the ability to produce large amounts of this material. Charcoal is a product that can be sold very easily. If there are byproducts, such as bio oil, cosmetic companies and other businesses will purchase this from you very quickly. All you need is a little bit of time to find these companies, assess them, and then choose the right one. Once you have done that, you can expect massive production and output from one of these top rated tire pyrolysis plant manufacturers.

After the acquisition of your very own tire pyrolysis plant, you will know that your due diligence has paid off. It will be efficient, and when you pay for it, it will be very affordable. The cost of tire pyrolysis plant is going to be minimal by comparison to how much you can make. You do not have one, or if you need to replace one that you have right now, start looking today for one of these pyrolysis plants that can help you convert tires into marketable products.