As the world grapples with the challenges of energy security and environmental sustainability, innovative technologies have emerged to address both issues simultaneously. Biomass pyrolysis and oil sludge pyrolysis are two such technologies that hold promise for transforming waste materials into valuable resources.

Resource Utilization

Biomass pyrolysis plant utilizes renewable resources as feedstock, promoting responsible land management and reducing reliance on fossil fuels. The availability of biomass sources such as crop residues, wood waste, and algae ensures a consistent supply for pyrolysis processes. This aligns with the principles of a circular economy, where waste is minimized, and resources are recycled. In contrast, oil sludge pyrolysis plants deal with a specific waste stream—oil sludge—that is generated in large quantities by the petroleum industry. By transforming this hazardous waste into valuable products like fuel oil and recovered metals, oil sludge pyrolysis contributes to resource recovery and waste reduction.

Environmental Impact

Biomass pyrolysis involves the thermal decomposition of organic materials such as wood, agricultural residues, and algae. It offers a sustainable solution by converting these materials into biochar, bio-oil, and syngas, all of which have various applications. Biomass pyrolysis helps reduce waste and carbon emissions by diverting organic matter from landfills and replacing fossil fuels. On the other hand, oil sludge pyrolysis plant deals with hazardous waste generated from oil extraction and refining processes. By converting oil sludge into usable products and minimizing its environmental impact, this technology aids in addressing the long-standing issue of oil industry waste disposal.

Biomass Pyrolysis Plant

Contributions to a Greener Future

Biomass pyrolysis plants play a significant role in the transition to a more sustainable future by enabling the utilization of renewable resources and reducing greenhouse gas emissions. Biochar sequesters carbon in the soil, improving soil quality and aiding in climate change mitigation. Bio-oil and syngas produced can serve as cleaner alternatives to fossil fuels, contributing to reduced reliance on non-renewable resources. Oil sludge pyrolysis plant contribute to environmental remediation by addressing a major waste issue in the petroleum industry. By converting oil sludge into valuable products, these plants reduce the environmental impact of waste disposal and support the principles of a circular economy.

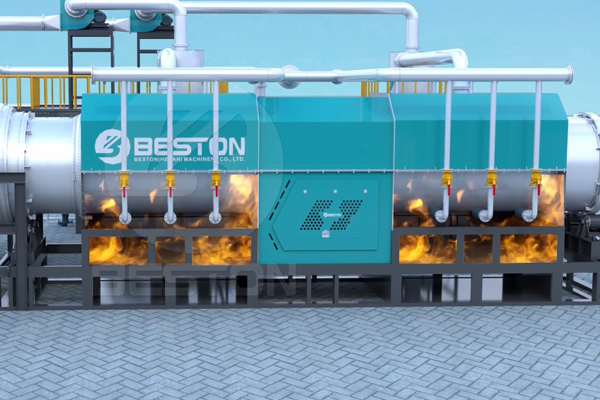

Oil Sludge Pyrolysis Plant

Technological Advancements

Both biomass pyrolysis and oil sludge pyrolysis have witnessed technological advancements in recent years. Biomass pyrolysis technologies have evolved to achieve higher efficiency, improved product yields, and better control over the pyrolysis process. This has led to a broader range of applications for the resulting products, such as bio-oil for energy and biochar for soil improvement. Similarly, oil sludge pyrolysis technologies have advanced to ensure the safe and effective treatment of hazardous waste. These advancements include optimized pyrolysis reactor designs, better waste pre-treatment methods, and enhanced product recovery systems. More Information can be obtained in Beston Group.