In the ever-evolving landscape of sustainable practices, biochar has emerged as an avant-garde solution, breathing new life into agriculture and offering transformative possibilities across various sectors. But what exactly is biochar, and how is it finding its footing in the modern world? Let’s embark on a journey through the realms of biochar application and unearth its multifaceted impact.

The Biochar Enigma

Biochar, an organic substance produced through the controlled thermal decomposition of biomass, is no ordinary player in the sustainability arena. It stands apart with its intricate carbon structure and exceptional potential. Often likened to charcoal, it is not to be confused with the charcoal produced for grilling purposes; rather, it is a highly specialized form with distinct applications.

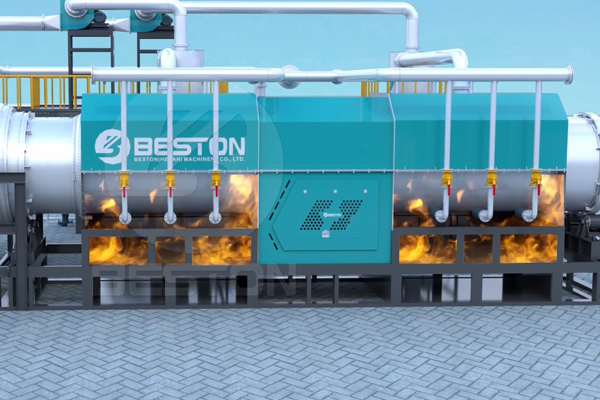

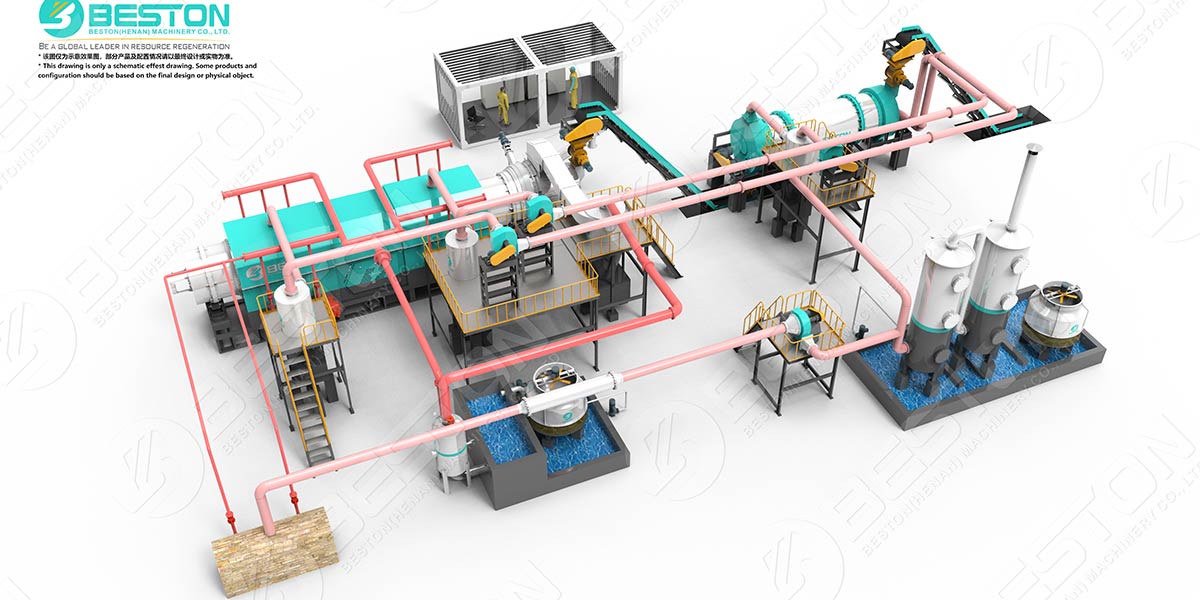

Biochar Production Equipment: Crafting Nature’s Marvel

The transformation from raw biomass to biochar is a meticulous process, demanding precision and specialized machinery. Charcoal maker machines or biomass carbonization machines, sometimes referred to as biomass pyrolysis plant, are the heart of this operation. These industrial marvels orchestrate the pyrolysis process with finesse, converting organic matter into the black gold that is biochar.

Unveiling the Versatility

Agriculture’s Green Ally

Biochar’s entry into the agricultural domain is nothing short of revolutionary. When introduced into soil, biochar ameliorates soil structure, enhances nutrient retention, and optimizes water management. Its porous structure acts as a reservoir for both water and nutrients, releasing them gradually to plant roots. The result? Improved crop yields, reduced soil degradation, and minimized dependency on chemical fertilizers.

In addition to these advantages, biochar fosters a haven for beneficial microorganisms, promoting soil health and mitigating harmful pathogens. This symbiotic relationship between biochar and soil heralds a paradigm shift in sustainable agriculture.

Carbon Sequestration Champion

Biochar from biomass carbonization machine is not just a boon for agriculture; it’s also a potent player in the fight against climate change. By locking carbon within its structure, biochar acts as a long-term carbon sink, keeping this essential element from escaping into the atmosphere as harmful carbon dioxide.

The carbon sequestration prowess of biochar opens the door to carbon credit programs, incentivizing its application in agriculture. Farmers and landowners can earn carbon credits, which can be traded or sold, thereby contributing to the reduction of greenhouse gas emissions.

Wastewater Treatment and Remediation

Beyond agriculture, biochar has made its mark in wastewater treatment and environmental remediation. Its sorptive qualities are harnessed for the removal of contaminants from water, making it a natural choice for water purification systems. In polluted environments, it acts as a soil remediation agent, rejuvenating damaged ecosystems.

Nurturing the Biochar Revolution

Biochar’s potential is far from exhausted, and research continues to uncover new applications and benefits. From enhancing the efficiency of biogas production to acting as a sustainable alternative for activated carbon, its role in a circular economy is expanding.

The Road Ahead

As the world grapples with the urgent need for sustainable practices, biochar application stands as a testament to human innovation and nature’s wisdom. It exemplifies the delicate balance between technology and ecology, offering solutions that resonate with the planet’s needs.

In this journey towards a greener future, the significance of biochar and its remarkable synergy with biochar equipment cannot be overstated. These elements embody the fusion of science and nature, unlocking new possibilities for agriculture, environmental restoration, and carbon management.

In a world where sustainability is the clarion call, biochar has taken center stage, and its application is redefining how we interact with our environment. It’s not just a substance; it’s a philosophy, a commitment to responsible resource management, and a symbol of hope for a more balanced, harmonious world.