There are several sellers of pyrolysis plants (пиролизные установки) all across the world. However, you will find that the manufacturers offering China pyrolysis plant for sale often offer the most value. More often than not, their prices are the lowest and if not the lowest, their prices are highly competitive and they typically have the shortest delivery times which means if you order a pyrolysis plant today, you should be able to get it within a few weeks. When you’re setting up a new business, getting the delivery of components required for setting up the new business is one of the most crucial aspects that can have a huge impact on the overall profitability of that business venture, and this is where Chinese manufacturers and sellers shine. Here are a few reasons why you should buy pyrolysis plants from manufacturers in China.

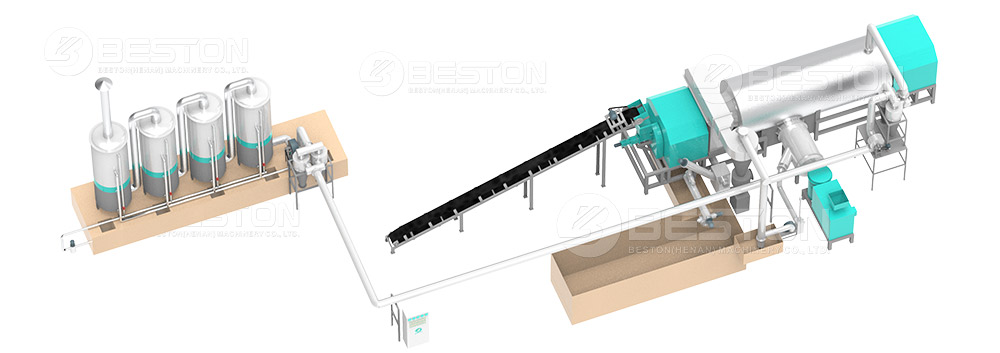

China Pyrolysis Plant

1. High Quality Products

One of the biggest reasons China has become a manufacturing hub for the global economy is that the manufacturers in China have been keeping up with the technology and are capable of delivering high quality products desired by buyers all over the world. While it is true that there are low quality manufacturers in China but it is also important to note that many manufacturers have invested a lot in technology upgrades and in training their engineers to be able to deliver the highest quality products to their customers. The only thing you need to be careful about is choosing the right manufacturer. So, do your research and choose a manufacturer with excellent reputation in the industry. One of the ways for you to check their reputation is to go through their customer reviews on various B2B trade portals where buyers leave ratings and reviews.

2. Save Money

One of the main reasons business owners around the world have been flocking to Chinese manufacturers is the competitive costs of all kinds of products in China. A pyrolysis plant is no exception and you are likely to find the Chinese manufacturers (like BG Environtechx) to be most cost competitive. They are able to offer lower prices as compared to the rest of the world due to huge economies of scale. The Chinese manufacturing sector is absolutely mind boggling. It is huge and manufacturers are easily able to source the raw materials required for making all kinds of machines quickly and at a cheaper rate. Also, the power is cheaper and labor is extremely cheap. All these things add up and help manufacturers cut down on costs as compared to the rest of the world and the companies are happy to pass on the savings to their customers.

China Pyrolysis Plant Price

3. Quick Delivery

Chinese companies are able to deliver quickly as compared to manufacturers elsewhere. Since Chinese companies get huge orders, the factories are always running which means they are constantly making products ordered by their customers. When the factories are running at full capacity, they are able to deliver products quickly and this is why, you can expect to get a pyrolysis plant ordered from a China-based manufacturer quicker as compared to manufacturers in other parts of the world.

Conclusion

Overall, there are a number of advantages of buying a pyrolysis plant from China-based manufacturers. They offer highest quality products at the lowest prices and they also deliver quickly. However, you need to be careful when choosing a manufacturer to get the most value for your money. So, do your research and find a reputable manufacturer to buy a pyrolysis plant from China (пиролизная установка купить из Китая) to set up a strong foundation for a successful business.