If you’ve decided that you want to buy a tyre pyrolysis plant, you’ll want to start looking at some of your options. You might be wondering how you can find a suitable tyre pyrolysis plant. If you’re ready to make this investment, you’ll quickly find that there are a lot of options worth considering.

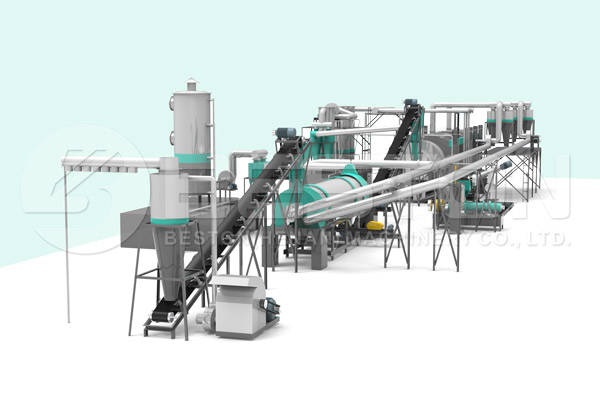

Scrap Tyre Pyrolysis Plant

Buy From An Excellent Vendor

The experience that you have when purchasing a pyrolysis plant is going to vary wildly based on the vendor that you purchase your plant from. There are vendors that will make things easier for you, and there are vendors that will create a lot of problems for you.

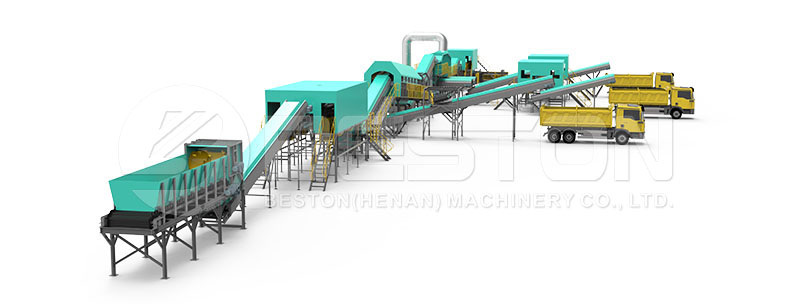

If you aren’t familiar with vendors that sell plants, you’ll want to do a little bit of research so that you can find vendors that are highly recommended. You may want to consider looking at vendors in different countries. There are vendors that sell these plants all over the world, and many of these vendors are excellent. Click here to know more about the continuous tyre pyrolysis plant.

Calculate Your Budget

Once you start looking at these plants, you’ll see that costs can vary wildly based on the plant that you buy. That’s why you’ll want to come up with a budget before you purchase your plant. You should decide what you’re willing to spend ahead of time.

If you know what your budget is, then you’ll be able to focus your attention on options that are within your price range. It will be easier for you to find affordable options, and you won’t waste any time looking at plants that are too costly for you.

You shouldn’t feel like you have to rush to make a purchase. It’s a good idea to look at a lot of the different choices that you have. You should try to educate yourself about your options so that you can find pyrolysis plant for sale that will do everything that you need them to do.

Most legitimate vendors will have plenty of information about the plants that they sell in their product descriptions. You’ll want to try to learn as much as you can so that you can pick out the best available plant.

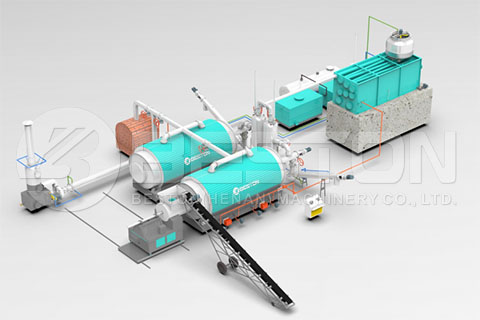

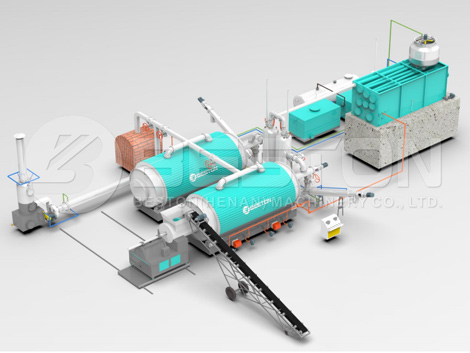

BLJ-10 Tyre Pyrolysis Machine to South Africa

Think About Your Needs

The best plant for one person might not be the ideal choice for another person. Not everyone that is investing in these kinds of plants is looking for the same things. For example, you might find that a small pyrolysis machine is the right choice for you. Others might be happier with a larger plant.

You shouldn’t take a one-size-fits-all approach when you’re selecting a plant. You should think about your own unique needs. Once you know what you’re looking for, you’ll be able to find excellent pyrolysis plants that work with you.

Since this is a major investment, you’ll want to make sure that you’re more than satisfied with the plant that you choose. You should identify some of the best options that are within your budget so that you can buy a plant you’ll be happy to use.