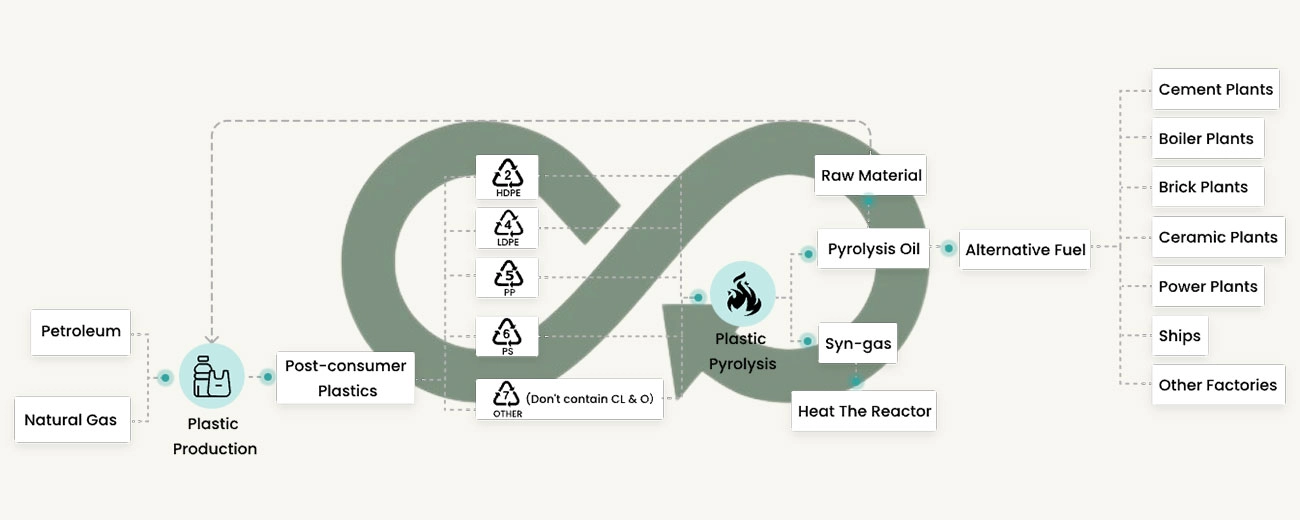

Plastic pollution is not just a problem; it’s a global crisis. Every year, millions of tons of plastic waste find their way into landfills and oceans, wreaking havoc on the environment and posing serious health risks. However, amidst this daunting challenge lies a promising solution: plastic pyrolysis. This innovative thermal decomposition process converts waste plastic into valuable oil that can be used to create new, high-quality plastics, thereby establishing a closed-loop circular economy.

Plastic to Oil via Pyrolysis

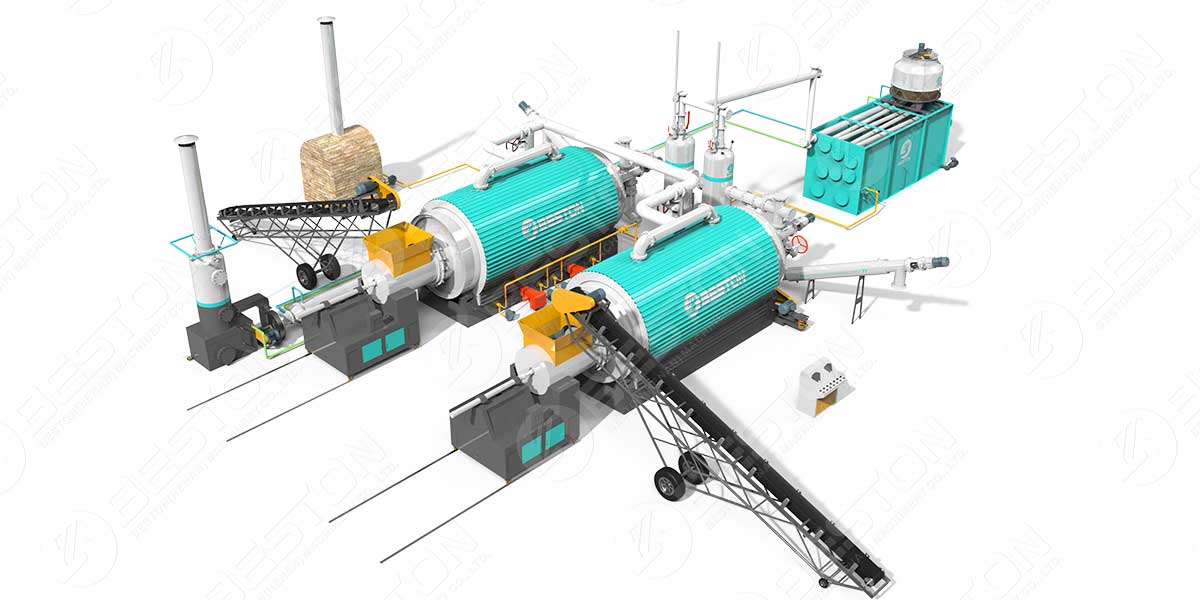

Pyrolysis involves heating plastic in an oxygen-depleted environment, breaking down long polymer chains into smaller molecules. This process yields a mixture of hydrocarbon liquids (oil), gases, and carbon black, the composition of which varies depending on the type of plastic used as feedstock.

Circular Economy Potential

The traditional linear model of plastic production relies heavily on extracting virgin fossil fuels, contributing significantly to environmental degradation. In stark contrast, plastic pyrolysis machine presents an opportunity to divert plastic waste from landfills and transform it into a valuable resource. This transition towards a circular economy holds numerous benefits:

- Reduced reliance on virgin fossil fuels: By minimizing the need for new oil extraction, plastic pyrolysis contributes to environmental conservation and sustainability.

- Mitigated plastic waste: Instead of accumulating in landfills or polluting natural habitats, waste plastic is repurposed, mitigating the global plastic pollution crisis.

- Energy recovery potential: The gases produced during pyrolysis can be captured and utilized as a source of fuel, further enhancing the process’s sustainability.

- Job creation: The development and scaling of pyrolysis facilities can potentially generate new employment opportunities across waste management, processing, and oil refinement sectors.

Applications of Pyrolysis Oil for New Plastics

The oil produced through plastic pyrolysis can be used in several ways to create new plastics within a circular economy:

- Chemical Feedstock: The oil can be further refined into chemical building blocks, or monomers, that are the basic units for making new plastic polymers. These “recycled monomers” can then be used to create virgin-quality plastics.

- Feedstock for Co-processing: Pyrolysis oil can be blended with virgin fossil fuels in existing plastic production facilities, reducing the reliance on virgin resources and increasing the overall recycled content of new plastics.

Circular Economy in Action

Integrating plastic pyrolysis into a circular economy framework requires a holistic approach. Here are some key elements:

- Improved Waste Collection and Sorting: Effective collection and sorting systems are crucial to ensure a consistent supply of clean plastic feedstock for pyrolysis plants.

- Standardization of Plastic Types: Standardizing plastic types used in products can simplify the sorting process and improve the quality and consistency of pyrolysis oil.

- Investment in Research and Development: Further research is needed to optimize pyrolysis technology, improve oil quality, and reduce production costs.

- Policy and Incentives: Government policies and incentives can encourage the development and adoption of plastic pyrolysis technology by creating a market for recycled plastics.

The Future Potential of Plastic Pyrolysis

Plastic to oil plant presents a promising solution for managing plastic waste and creating a more circular economy for plastics. While challenges remain, advancements in technology, combined with improved waste management practices and supportive policies, can pave the way for a more sustainable future for plastics.

Here are some additional points to consider:

- Integration with Other Recycling Technologies: Plastic pyrolysis can be integrated with other plastic recycling technologies, such as mechanical recycling, to create a multi-pronged approach to managing plastic waste.

- Life Cycle Assessment: Life cycle assessments are needed to evaluate the environmental impact of plastic pyrolysis compared to other plastic waste management options.

- Public Awareness: Raising public awareness about the benefits of plastic recycling and the potential of pyrolysis can encourage responsible waste management practices.

By embracing innovation and adopting a circular economy approach, plastic pyrolysis to oil can play a significant role in mitigating plastic pollution and creating a more sustainable future for this ubiquitous material. Feel free to inquire for additional details at Beston Group.